Material Separation & Water Treatment

Three Decades of Delivering Reliable Water Treatment & Separation Systems

Separation Equipment Manufacturers in Illinois

At Illinois Dredging, we specialize in providing top-tier material separation and dewatering solutions that meet the evolving needs of dredging operations across the state. As trusted manufacturers of separation equipment in Illinois, we deliver reliable, high-performance systems designed to address sedimentation challenges in inland waterways, urban environments, and regulated wetland zones. Our portfolio includes advanced sedimentation tools, integrated material separation services in Illinois, and next-generation separation technology engineered to maximize throughput and reduce project delays.

Backed by years of field experience, our custom-built separation equipment ensures precision in removing solids from slurry, making it easier to transport, dispose of, or repurpose dredged materials. Whether your project faces environmental compliance hurdles or tight turnaround timelines, Illinois Dredging delivers practical, scalable solutions that maintain productivity without compromising on environmental responsibility.

Material Separation & Water

Treatment Equipment

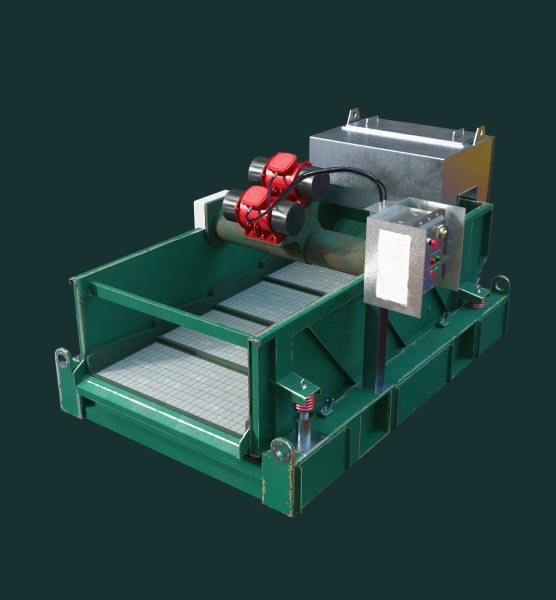

Patented Vacuum Dewatering System for Slurry Management

Our patented slurry vacuum dewatering system sets a new standard for efficiently drying dredged materials. This vacuum-powered solution is built to outperform traditional drying techniques by accelerating dewatering cycles and reducing moisture content with unmatched speed. For projects facing wintertime restrictions or strict discharge permits, this system ensures continuity of operations with minimal disruption.

At Illinois Dredging, we go beyond dewatering. We offer comprehensive industrial water treatment services, including filtration, clarification, and solids management, tailored to support clients in the dredging, construction, and energy sectors. Whether you’re tackling a contaminated sediment removal project or need support with ongoing sludge processing, we provide commercial water treatment solutions that meet regulatory requirements and safeguard public infrastructure.

Speed, Scalability, and Efficiency

Unlike slower belt-press or centrifuge systems, our vacuum dewatering systems are engineered to handle high volumes with consistent efficiency. These systems are compatible with most dredge setups due to their modular design, enabling fast deployment in constrained urban or marshy project zones, key for operations navigating tight access points or Illinois’ fluctuating seasons.

High-Performance Dewatering Vacuum Pumps

Every system we deploy is anchored by high-capacity dewatering vacuum pumps, purpose-built to manage abrasive slurries and fine sediments. Whether it’s for power plant intakes, municipal lagoon restoration, or wetland recovery, our pump and dewatering packages are tuned for durability and continuous duty under harsh conditions.

Cleaner Results with Enhanced Slurry Separation

Our integrated slurry separation technology improves both liquid clarity and solid consolidation, reducing the load on downstream treatment while improving handling logistics. This not only ensures compliance with eco-friendly water treatment methods but also reduces waste disposal costs.

Geotextile Tubes for Dewatering and Sediment Management in Illinois

At Illinois Dredging, we understand the complexities of managing sediment in a state challenged by seasonal extremes, urban constraints, and strict regulatory oversight. Our advanced geotextile tubes offer a practical and proven solution for projects that require effective solid-liquid separation, eliminating the need for heavy infrastructure or costly processing equipment. Whether you’re managing silt buildup in inland waterways or clearing contaminated material near critical urban zones, our geotextile tube systems are built to perform.

When you partner with Illinois Dredging, you’re choosing a team that doesn’t just supply equipment—we deliver smart, site-specific dewatering strategies. Our commitment to performance, sustainability, and cost-efficiency makes us the go-to choice for geotextile tube dewatering technology and full-scale sediment management across the state.

High-Capacity Dewatering Geotextile Tubes

Our dewatering geotextile tubes are engineered for high-volume sediment containment, making them ideal for Illinois’s large-scale dredging project, especially in river systems prone to accelerated sedimentation. These sediment dewatering tubes can store substantial amounts of dredged material, allowing for uninterrupted operations and minimizing the need for frequent tube changes or hauling delays.

Cost-Efficient and Scalable

Budget constraints are common across Illinois dredging projects, whether public or private. That’s why Illinois Dredging offers Geotextile Tube Dewatering Technology as a low-cost alternative to mechanical presses or vacuum systems. These tubes reduce equipment needs, minimize labor, and cut overall disposal costs, making them especially useful for municipalities and floodplain restoration efforts working within limited funding windows.

Environmentally Responsible Dredging

We understand the importance of environmental compliance in the Midwest, particularly with stringent sediment discharge regulations and protected wetland areas. Our sediment dewatering tubes help meet those standards. Designed to filter out solids while allowing clean water to return to its natural system, they support eco-friendly dredging practices across Illinois. Whether the material is lightly contaminated or regulated for disposal, our tubes contribute to responsible site restoration and habitat protection.

Optimized Separation Performance

Using advanced Geotextile Tube Dewatering Technology, our tubes deliver superior results across a wide range of sediment conditions. They effectively capture fine particles, which is especially important in areas where clay and silty materials dominate the dredging profile. This means cleaner effluent and reduced sediment reintroduction, which is critical in downstream municipal water sources and flood control zones.

Built for Illinois’ Diverse Projects

Our geotextile tubes are adaptable to a wide range of project scopes, from dredging near aging infrastructure in Chicago to managing floodplain sedimentation in rural southern Illinois. We’ve designed these solutions to handle everything from urban stormwater projects to industrial dredging, offering reliability and performance across every application.

Customized Pond Dredging and Dewatering Solutions

At Illinois Dredging, we understand that effective water and sediment management often requires more than just equipment—it takes a strategic approach. Our temporary pond excavation and dredging services are designed to support dewatering operations where space, flow control, and sediment settling are critical to the success of a dredging project. From urban infrastructure constraints to flood-sensitive zones, our team delivers smart, scalable, and regulatory-compliant dewatering pond construction services.

Tailored Pond Excavation for Efficient Sediment Control

Our approach starts with customized dredging for ponds, where we evaluate each site’s terrain, sediment type, and discharge parameters. Every temporary pond we construct is engineered for performance, whether you’re working near a water treatment facility or managing stormwater runoff from dredging activities near wetland buffers. These ponds allow solids to settle before discharge, helping meet environmental benchmarks and avoid fines.

Practical Sediment Management for Real Conditions

Illinois faces significant issues with sedimentation in its inland waterways, particularly in aging stormwater and drainage networks. Our pond restoration dredging teams build temporary containment systems that give you time to process and manage sediment without halting operations. These ponds act as a buffer zone, letting you decant cleaner water while isolating heavier material for later removal or treatment.

Rapid Setup, Zero Waste of Time

Our team knows that time lost is money spent. That’s why our custom pond dredging solutions are deployed fast and built for immediate use. Whether your site is in a suburban floodplain or an industrial corridor along the Mississippi, we deliver Illinois pond dredging support with speed and precision, without compromising safety or performance.

Flexible for Every Project Type

Whether you’re working with pond dredging consultants on a private agricultural site or handling a high-volume urban dewatering effort, our temporary pond systems scale to match your needs. From compact containment setups to larger pond dredging operations, we design every solution with the end goals in mind: cleaner water, captured solids, and minimal environmental disruption.

A Smarter, More Cost-Effective Choice

Unlike permanent installations, our dewatering ponds are designed to be temporary, offering full functionality during the dredging phase and allowing for simple removal afterward. This makes them the go-to option for projects working within budget and funding limitations, as well as those navigating seasonal or weather-driven delays across Illinois.

Industrial Water Treatment Dredging & Separation Solutions

At Illinois Dredging, we specialize in delivering advanced industrial water treatment services that effectively remove contaminants from dredged water. Our comprehensive approach combines proven treatment methods with the latest technology to ensure that every drop meets or exceeds the strictest environmental regulations. Designed to support everything from material separation and water treatment equipment to eco-friendly water treatment methods, our systems are built for performance and compliance across Illinois’ most demanding dredging projects.

Initial Screening & Pre-Treatment

Our treatment starts with coarse screening systems designed to intercept large debris and sediment early in the dredging process. This is especially important in urban infrastructure-constrained projects where equipment damage or clogging can delay progress.

Coagulation and Flocculation

Next, we initiate chemical treatment using coagulants that bind fine particles into flocs. This step is crucial in industrial water treatment services, particularly in regions where contaminated sediments from manufacturing runoff or legacy pollutants are prevalent.

Sedimentation

Clarified water is transferred into settling basins where flocs settle to the bottom. This collected sludge is then removed for compliant disposal. Combined with geotextile tubes, this step becomes even more efficient, reducing space usage and maximizing sediment consolidation, especially useful in tight-access locations.

Filtration

We use a combination of sand, gravel, and membrane-based filtration systems to remove any remaining particles. Our solutions are engineered for both large-scale dredging sites and compact projects needing commercial water treatment solutions in densely populated Illinois zones.

Advanced Oxidation (AOP)

Through ozone injection, hydrogen peroxide dosing, and UV treatment, we break down organic pollutants, especially important when dealing with the disposal of contaminated sediment near environmentally sensitive areas, such as wetlands or drinking water sources.

Adsorption

Using activated carbon beds, we remove residual compounds that affect taste, odor, or chemical composition. This level of refinement supports eco-friendly water treatment methods and enhances environmental safety prior to final discharge.

Disinfection

To ensure complete pathogen removal, we utilize UV systems or chlorination, depending on the project scope. These disinfection stages are critical to meeting standards for water released near public spaces or agricultural runoff areas.

Monitoring & Regulatory Compliance

Our monitoring systems are calibrated to track flow, pH, turbidity, and other key parameters in real-time. Additionally, we conduct laboratory testing and sampling as part of our wastewater treatment services to confirm compliance with Illinois EPA and Army Corps of Engineers standards.

Our Water Treatment Process

Drawing from industry best practices and advanced water treatment equipment, Illinois Dredging follows the below multi-stage process to deliver efficient, compliant, and eco-friendly water treatment solutions:

Coagulation and Flocculation

Process

Positively charged chemicals are introduced to neutralize and bind negatively charged particles.

Outcome

Formation of larger flocs, improving the removal of suspended contaminants.

Sedimentation

Process

Floc particles settle naturally in sedimentation tanks under gravity.

Outcome

Clear water separates from sludge, preparing for further filtration.

Filtration

Process

Water passes through layers of sand, gravel, or membranes to remove remaining particulates.

Outcome

High-clarity water free of residual solids and impurities.

Disinfection

Process

Application of chlorination, UV light, or ozonation to target pathogens.

Outcome

Elimination of harmful microorganisms to ensure water safety.

pH Adjustment

Process

Chemical balancing to stabilize the water’s pH and prevent corrosion.

Outcome

Neutral pH levels are safe for infrastructure and end use.

Optional Fluoridation

Process

Fluoride is added where required to enhance dental health.

Outcome

Community benefit through reduced risk of tooth decay.

Final Treatment and Distribution

Process

Treated water is stored in reservoirs and monitored for quality before use.

Outcome

Consistent delivery of safe, high-quality water for municipal, industrial, or environmental applications.

Let Illinois Dredging Support Your Next Project

Contact us today to schedule a consultation or to learn more about our services.